BEYOND | call for projects

ENTRY #39 | adaptive modules

Project Brief

Technical details about the project:

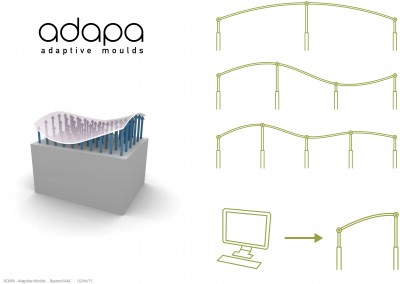

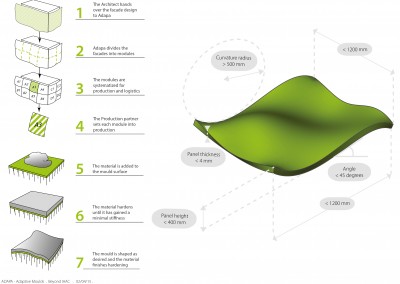

The basic product is the adaptive mould technology that can produce elements in various materials directly from CAD drawings.

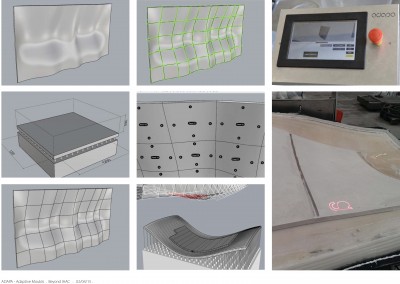

The secondary product is software used for the preparation and analysis of CAD surface data for the mould and subsequent control of the mould and as a tool for production control.

Technical description

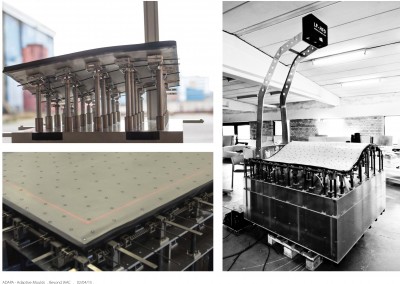

The adaptive mould technological centerpiece is the digitally controlled actuators, which defines a set of points, which the membrane interpolates a surface between. The membrane adopts a surface shape with a minimum of deflection through the set of points. In addition, we have developed a CAD program from which control of the Adaptive Mould takes place and project management when the mould is included in the production of several elements.

The actuators are controlled digitally via a central engine control unit which is controlled by an HMI (Human Machine Interface) assigned position, speed and security analysis. The HMI is connected to a server from which the position will be retrieved via a computer where the production employee can check which surfaces to be produced from the project management application on the server.

The membrane is specifically designed for the purpose, and constitutes the patented invention. It is characterized by having a stiffness in bending while at the same time being easy to extend, in its own plane. This means that it may take a double-curved shape, and by its rigidity that the surface of this type will be smooth and uniform in all directions. It is also possible to design the membrane in order to achieve greater rigidity in certain directions with respect to the others.

The membrane is attached to an underlying system of rails and brackets, which allow it to expand freely under deflection in a manner in which points on the surface of the membrane can still be predicted accurately from the actuators positions. Along the edge of the membrane the precise angle is controlled so as to ensure a continuous transition from a single moulded element to another.

Software description

Parallel to the development of the mould we are developing software for the control of the Adaptive Mould in CAD. Multiple plugins are being developed based on the Adaptive Mould and relevant 3D transformations. First the main plugin for Rhino 3D is developed and an external Case Handler, later more advanced plugins for the various CAD systems, such as Catia, Solidworks and Pro-engineer will be developed.

The plugins may also be used in projects and which is not based on the mould.

Project Credits

Christian Jepsen

Jakob Filso

Stasys Montyvadys

Octavian Richea

Affiliation/Organisation:

Adapa ApS, Denmark